Cutting optimisations

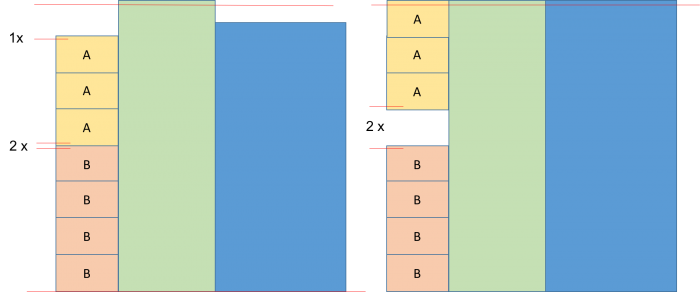

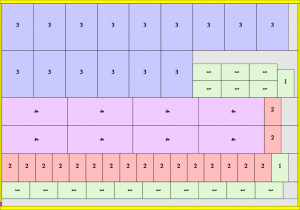

Let ‘s assume each order requires a bleed. This means that a double cut is necessary, regardless of other factors, to split two replicas from each other. By moving one replica towards the outermost border, one may save one cut on the cutting-machine (see figure).

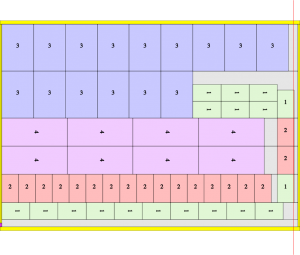

When two (or more) different kinds of replicas are lying in a stroke, one can move the two kinds from each other until they reach the stroke-border. In this case, we say we are spreading a stroke in the length direction. When only one kind of replica lies in the stroke, then we can move 1 replica towards the stroke border. We call this: spreading a shelf in the length direction.

Spreading the stroke in the length direction

Spreading a shelf in the length direction

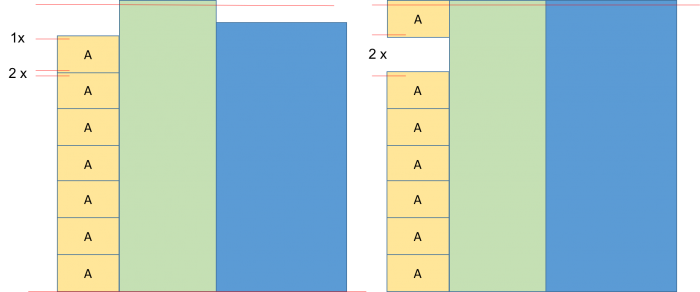

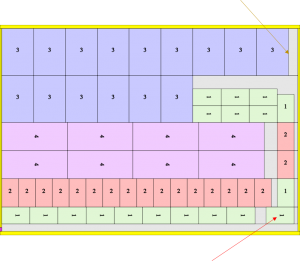

The same principal goes for the width direction of a stroke. By aligning replicas to the side border of a stroke, again one or more cutting operations may be saved (see figure).

Spreading a shelf in the width direction

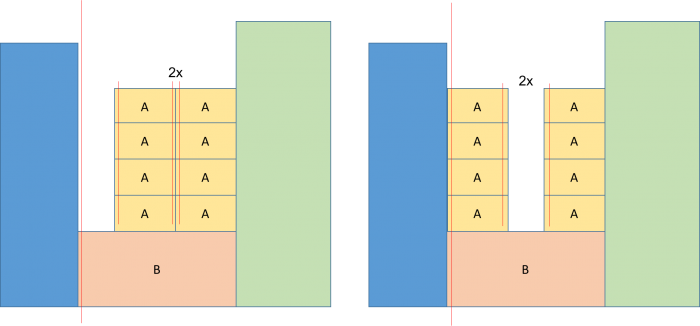

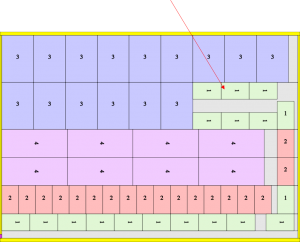

Combining the spreading in length and the spreading in width of a shelf typically leads to a ‘central cross’:

Spreading a shelf in the length- and in the width-direction

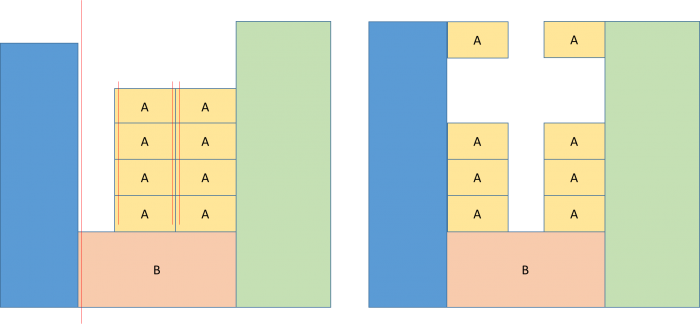

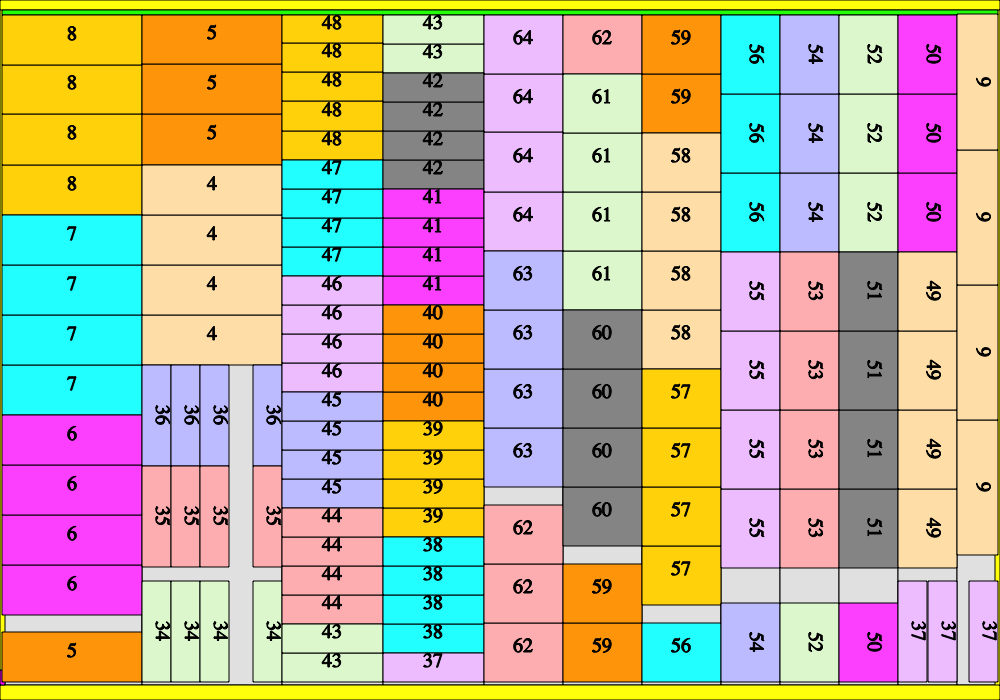

Applying this on a specific case, step by step, gives the following:

Starting point: no optimisation

Spreading strokes in the length-direction.

Spreading shelves in the length direction

Note: in the figure above, notice that the replica’s of article 3 are not spread, since article 3 has to be punched, and should remain united.

Spreading shelves in the width direction

In the production configuration file, the following parameters should be specified:

- Spreading a stroke in the length direction: (yes / no)

- For each finishing-routing (final cutting, punching or cutting into strokes, die cutting):

- Spreading shelves in the length direction: (yes / no)

- Spreading shelves in the width direction: (yes / no)

Without cutting optimisation

With cutting optimisation