Punching (Polar, Blumer)

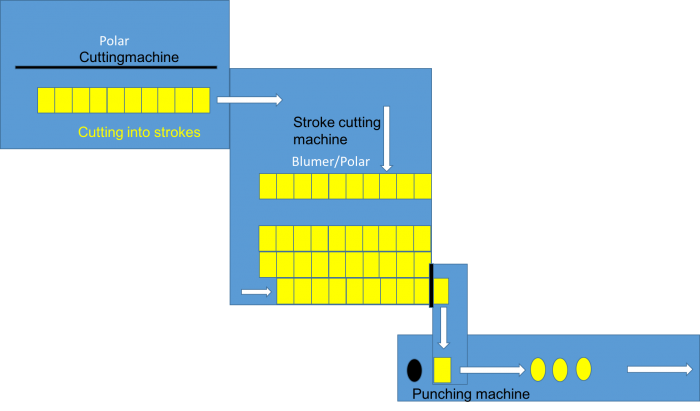

In order to feed for a punching-line well, it is more efficient to deliver strokes as input instead of separate packages of orders. This way, the punching unit may produce continuously at maximum capacity. This is possible with a combined production-line for guillotine-cutting + stroke-cutting + punching, like Polar and Blumer offer to the printing industry.

Such production-lines are very efficient, but impose restrictions on the ganging-combinations allowed for production.

In order to feed the punching unit continuously, there are a number of conditions: 1) replicas should be arranged across a stroke and 2) the strokes should have a minimum length. Indeed, the guillotine cutting of the strokes requires some time, as well as the feeding of the stroke cutting machine. One may set for example a minimum stroke length of 12 inches (30cm) for the stroke cutting machine. This only for strokes with the same punchID, so that the punching unit does not require an additional setup.

When a stroke contains 2 different punchID’s, then each part should be at least 12 inches long.

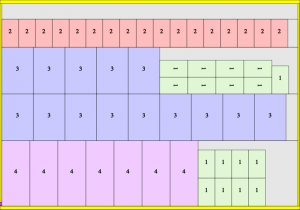

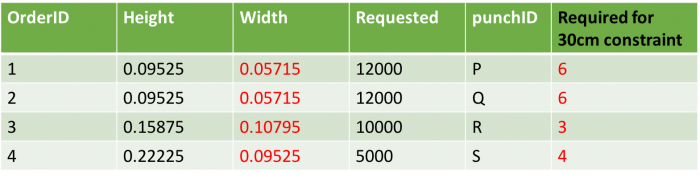

Consider the next example of 4 articles (orders). When they are arranged across in a stroke, they require respectively 6, 6, 3 and 4 replicas near each other in a stroke, to reach a length of 12 inches.

We will now compute all the different combinations for the different orders with and without punchID. When article 1 has a punchID, we will identify this punching-knife with ‘P’, for article 2 we will use ‘Q’ and so on. A combination is indicated as (_ _ R S) for example, meaning that article 3 has a punchID ‘R’ and article 4 a punchID ‘S’, while articles 1 and 2 have no punchID (because they are normal articles).

We will now compute all the different combinations for the different orders with and without punchID. When article 1 has a punchID, we will identify this punching-knife with ‘P’, for article 2 we will use ‘Q’ and so on. A combination is indicated as (_ _ R S) for example, meaning that article 3 has a punchID ‘R’ and article 4 a punchID ‘S’, while articles 1 and 2 have no punchID (because they are normal articles).

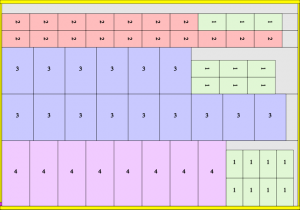

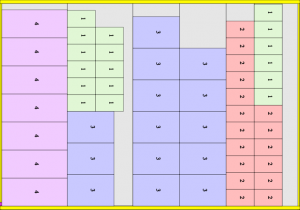

(_ _ _ _) None of the articles has a punchID

The result above shows what is obtained when no punchID is specified. All articles may be placed along or across in a stroke and the 12 inch constraint is required nowhere.

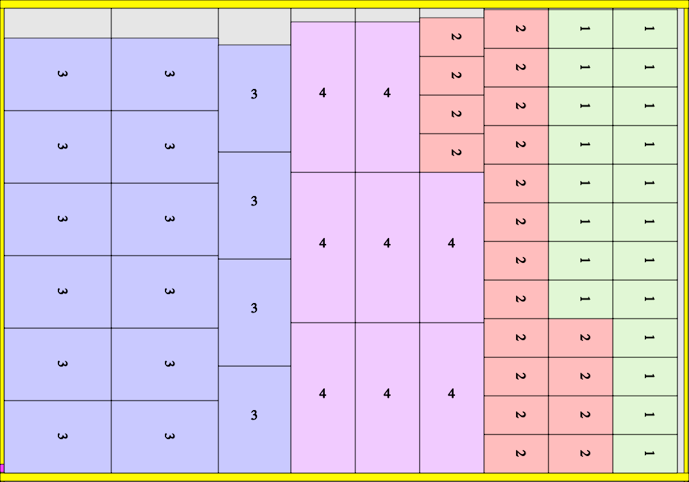

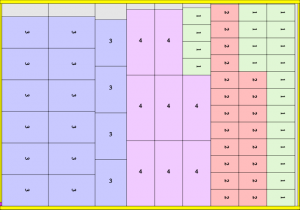

(_ _ _ S) Article 4 has a punchID.

In this figure, article 4 has a punchID. As a consequence, article 4 has to be placed across in a stroke and the minimum stroke length should be 12 inches. This implies that at least 4 replicas of article 4 should be placed after each other.

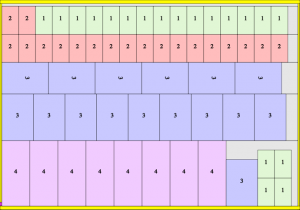

(_ _ R _) Article 3 has a punchID

When article 3 has a punchID, it should appear with at least 3 replicas in a stroke.

Note that, in the following examples as well, the constraint is always satisfied, each time with different impositions.

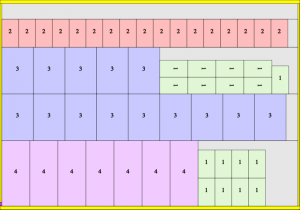

(_ _ R S) Articles 3 and 4 have 2 different punchID’s

(_ P _ _) Article 2 has a punchID P

Article 2 should appear with at least 6 replicas near each other arranged across in a stroke.

(_ P _ S)

Articles 2 and 4 should now both satisfy the 12 inch-constraint.

(_ P R _) Articles 2 and 3 satisfy the 12 inch constraint

( _ P R S)

Articles 2, 3 and 4 must now all 3 satisfy the 12 inch-constraint.

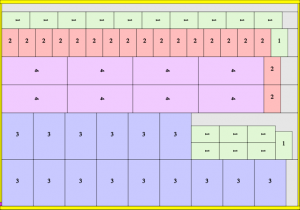

We could show you all other combinations, but we will limit us here to provide you at least with the impositions where all articles should satisfy the 12 inch-constraint.

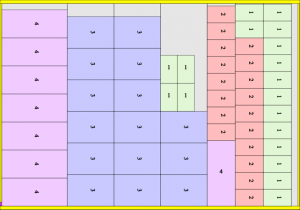

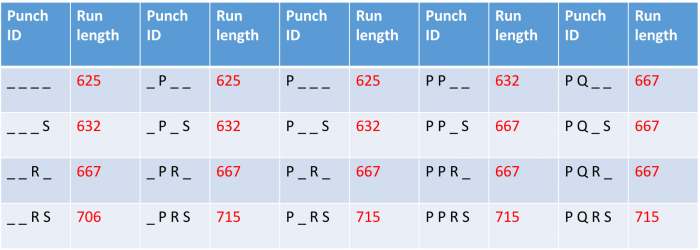

As you will notice, putting more punching constraints on different articles, each time leads to a somehow less filled imposition. An overview:

Remark the run-length rises from 625 sheet, when no punch-constraints are imposed, until 715 sheet when the maximum of constraints are applicable. This means it is always interesting to combine punching-articles with none-punching-articles, when possible.